|

| February 15, 2022 | Volume 18 Issue 07 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Cool Designs: MEMs microspeakers made entirely from silicon

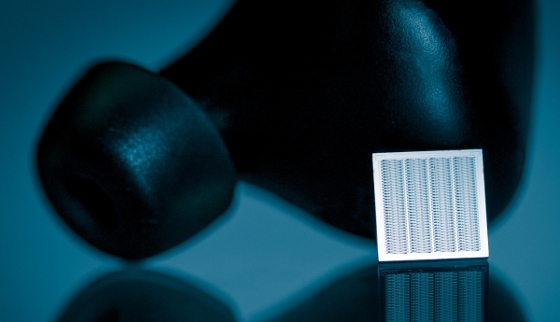

An Arioso Systems silicon microspeaker in front of a typical wireless in-ear headphone. [Credit: © Arioso Systems GmbH]

New microspeakers for wireless in-ear headphones from Arioso Systems GmbH, a spin-off of the Fraunhofer Institute for Photonic Microsystems IPMS, are up to 10 times smaller than conventional microspeakers and are made entirely from silicon. The energy-efficient MEMS speaker technology is made possible by an innovative sound transducer principle that dispenses with the membrane, the central element of a conventional speaker.

Currently at the prototype stage, the energy-efficient micro-electromechanical (MEMS) speakers could one day help expand the range of functions offered by miniaturized headphones such as instant translations and health monitoring.

Wireless in-ear headphones are a growing trend, but they are still relatively large, and many of their components drain batteries quickly. New intelligent functions require lots of computing power -- and lots of space and electricity. The bulkiest components of newer wireless earphones are the battery and the microspeaker.

The new microspeakers from Arioso Systems measure just 10 to 20 mm2, making them ideal for future wearable applications, such as simultaneous translation, payment functions, and other voice-based internet services. The Dresden-based Fraunhofer IPMS spin-off was founded in 2019 and now has 12 employees.

Unlike conventional speakers and the few other MEMS speakers in existence, the tiny speakers from Arioso Systems do not contain a membrane or magnets. Instead, they are formed entirely from silicon. They can be mass-produced cost effectively using standard CMOS processes, making them easy to scale for the mass market.

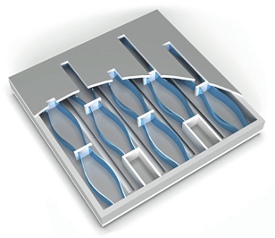

Lamella-like bending beams inside the new MEMS microspeaker generate the sound. [Credit: © Arioso Systems GmbH]

The speakers use a new, power-efficient sound transducer principle. This is based on Nanoscopic Electrostatic Drive (NED) technology, which was developed by Holger Conrad, a founding member of Arioso Systems, during his time at Fraunhofer IPMS. Unlike conventional speakers, the new MEMS sound transducer has no membrane. It has been replaced by a large number of thin bending beams, each measuring 20 µm, contained within the silicon chip. Air escapes from openings on the top and bottom of the chip and flows into the chambers, where electrostatic actuators move. The application of an audio signal voltage causes these NED actuators to bend. The vibrations are then heard as sound.

"The lamella-like bending beams move toward each other and push the air out at the top and bottom, causing pressure fluctuations in the ear that are audible," explained Arioso CFO Dr. Jan Blochwitz-Nimoth. "In principle, the eardrum is moved directly like it would be with an air pump."

Because the components can be integrated directly in the silicon chip, they take up little space and are much more energy efficient than conventional speakers. The technology uses less battery, extending the battery life by several hours.

"The sound is generated inside the silicon chip. The fact that there are no outer moving parts such as membranes frees up space and reduces the number of assembly steps in the production process," said Arioso CEO Dr. Hermann Schenk. "The thin lamellas inside the chip are moved by applying an electrical voltage. This generates a sound pressure level of (up to) 120 dB, with optimum sound quality over a chip area of just 10 millimeters square."

Arioso Systems describes the overall high-fidelity sound quality as "crystal clear."

Currently, Arioso Systems is directing its development toward the needs of large OEMs, and internet service providers in particular. The innovative sound transducer principle is also suitable for use in hearing aids.

A seed funding round has been closed, and the spin-off has so far received 2.6 million euros from investors. Over the next two to three years, the prototype MEMS microspeakers are set to be scaled up from lab to pilot scale.

If you are interested in reviewing journal papers about this technology, go to arioso-systems.com/scientific-contributions-microspeakers/.

Source: Fraunhofer Institute for Photonic Microsystems IPMS

Published February 2022

Rate this article

View our terms of use and privacy policy